INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING

SkyGeek welcomes international orders!

Please note: such orders are funneled into our NY warehouse and may take an extra 7-10 days to process. The benefit to this: You get one package shipped which reduces added taxes and duties that may be incurred from multiple shipments.

HAZMAT ORDERS

HAZMAT ORDERS

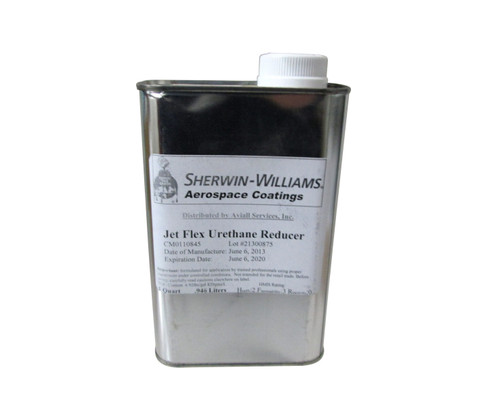

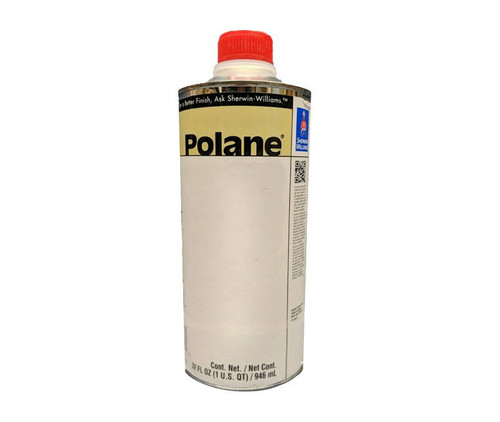

Safety Data Sheet

Warning: This product may contain a chemical known by the State of California to cause health issues. Details found here www.p65warnings.ca.gov

UN Number: UN1263

UN Class: 3

Country of Origin

Country of Origin