-

Henkel 2728949 BONDERITE® M-CR AERO Touch-N-Prep® Pen Felt Replacement Slim Tip - 12/Pack

Henkel 2728949 BONDERITE® M-CR AERO Touch-N-Prep® Pen Felt Replacement Slim Tip - 12/Pack

PART #: SGP210211-X12MFR PART #: 2728949Our Price: $121.92 (12/Pack)QTY: Add to Cart -

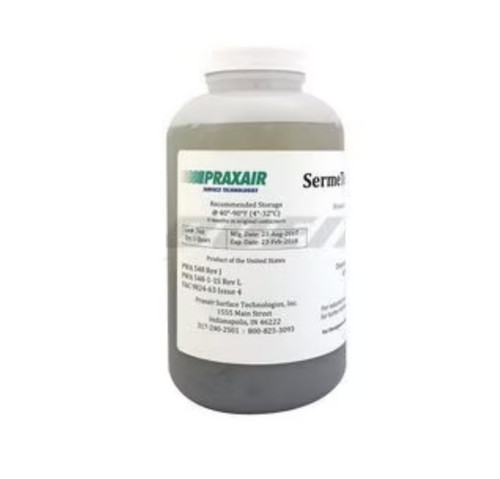

SermeTel® 1382 Gray Two-Part Epoxy Repair Coating - A+B Quart Kit

SermeTel® 1382 Gray Two-Part Epoxy Repair Coating - A+B Quart Kit

PART #: SGK325MFR PART #: 915-ST1382QTOur Price: $1,225.35 (Kit)QTY: Add to Cart -

SermeTel® 273 Red BMS14-4 Type 2 Spec Coating Catalyst - Gallon Jug

SermeTel® 273 Red BMS14-4 Type 2 Spec Coating Catalyst - Gallon Jug

PART #: SGP211244MFR PART #: 915-ST273Our Price: $852.11 (Each)QTY: Add to Cart -

SermeTel® 750 Brown PWA487-1S & MSSR9365 Spec Air Dry Touch-Up Coating - Pint Can

SermeTel® 750 Brown PWA487-1S & MSSR9365 Spec Air Dry Touch-Up Coating - Pint Can

PART #: SGP211218MFR PART #: 915-ST750PTOur Price: $309.86 (Each)QTY: Add to Cart -

SermeTel® 249 Gray PWA548-1S Spec Aqueous Inorganic Metallic Coating - Gallon Jug

SermeTel® 249 Gray PWA548-1S Spec Aqueous Inorganic Metallic Coating - Gallon Jug

PART #: SGP211217MFR PART #: 915-ST249Our Price: $1,011.74 (Each)QTY: Add to Cart -

SermeTel® 1072 Gray High-Temperature Polymer Coating with Metallic Pigmentation - Pint Can

SermeTel® 1072 Gray High-Temperature Polymer Coating with Metallic Pigmentation - Pint Can

PART #: SGP211216MFR PART #: 915-ST1072PTOur Price: $1,246.48 (Each)QTY: Add to Cart -

Henkel 2728948 BONDERITE® M-CR AERO Touch-N-Prep® Pen Felt Replacement Wide Tip - 12/Pack

Henkel 2728948 BONDERITE® M-CR AERO Touch-N-Prep® Pen Felt Replacement Wide Tip - 12/Pack

PART #: SGP54073-X12MFR PART #: 2728948Our Price: $74.16 (12/Pack)QTY: Add to Cart -

Henkel 597168 BONDERITE® S-MA 5580-G Light Green Hand-Strippable Coating - 55 Gallon Barrel with Bung - 10/Pack

Henkel 597168 BONDERITE® S-MA 5580-G Light Green Hand-Strippable Coating - 55 Gallon Barrel with Bung - 10/Pack

PART #: SGP53989-X10MFR PART #: 597168Our Price: $52,333.50 (10/Pack)QTY: Add to Cart -

Henkel 611588 BONDERITE® M-AC M White Powdered Conditioning Agent - 100 lb Barrel with Lid

Henkel 611588 BONDERITE® M-AC M White Powdered Conditioning Agent - 100 lb Barrel with Lid

PART #: SGP55989MFR PART #: 611588Our Price: $4,320.76 (Each)QTY: Add to Cart -

Henkel 594838 BONDERITE® C-IC 172A Phosphoric Acid Metal Cleaner & Surface Rust Remover - 277 Kg Barrel with Bung

Henkel 594838 BONDERITE® C-IC 172A Phosphoric Acid Metal Cleaner & Surface Rust Remover - 277 Kg Barrel with Bung

PART #: SGP53874MFR PART #: 594838Our Price: $1,660.63 (Each)QTY: Add to Cart -

Henkel 594339 BONDERITE M-AD 95B Amber Pretreatment Additive - 5 Gallon Closed Head Pail with Bung

Henkel 594339 BONDERITE M-AD 95B Amber Pretreatment Additive - 5 Gallon Closed Head Pail with Bung

PART #: SGP53855MFR PART #: 594339Our Price: $1,049.82 (Each)QTY: Add to Cart -

Henkel 1006652 BONDERITE® M-CR 1600™ AERO Orange-Red Hexavalent Chromate Conversion Coating - 5 Gallon Closed Head Pail with Bung

Henkel 1006652 BONDERITE® M-CR 1600™ AERO Orange-Red Hexavalent Chromate Conversion Coating - 5 Gallon Closed Head Pail with Bung

PART #: SGP13988MFR PART #: 1006652Our Price: $1,249.50 (Each)QTY: Add to Cart

Beauty is only skin deep, but there’s nothing wrong with appreciating a pretty plane, Makes sure your aircraft is ready for paint or refinishing by using a metal prep product from SkyGeek. Take the easy route and let our powerful metal prep solutions do the hard work for you, getting surfaces ready to accept paint or primer. Our selection of premium preparation products includes things like Metalprep 79 for cleaning and conditioning, alkaline cleaners and plenty of conversion coating products designed to enhance paint adhesion while blocking corrosion. Our metal prep collection includes all of your favorite brands, with products for DIYers or professionals.

Cleaners

The first step to getting your aircraft ready to paint is to clean the surface. You’ll be surprised how much dirt and grime can accumulate on an aircraft after spending time in the sky. Blast away surface debris with a powerful cleaner and reveal a pristine surface that’s ready for a color application. Our cleaners are often all you need to work on a previously painted surface. Pick out a cleaner and conditioner combo to tackle tough jobs.

Conversion Coating Products

When a topcoat just won’t be enough, a conversion coating might deliver the protection and finish you need. At SkyGeek, we carry a variety of conversion coating products to choose from that are designed to interact with the metal surface of your aircraft to create a sleek, smooth new finish. As a bonus, many conversion coating products also reinforce the surface, adding hardness and an additional layer of protection against the elements. Conversion coating products work best on alloys like aluminum.

Give your aircraft a fresh new finish with metal prep products from SkyGeek. When beauty is only skin deep, we have the tools you need to completely refresh your finish. While you’re here, be sure to also check out our impressive selection of paint and primer supplies at great prices.