Related Items

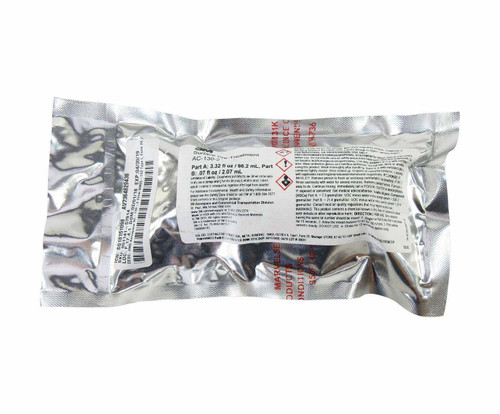

3M™ Aerospace AC-130-2 Clear BMS5-162 Type I, Form 2S Spec Surface Pre-Treatment - 100 mL Kit

PART #:

SGP5166

MFR PART #:

7000048183

Regular Price:

Our Price:

Our Price:

Sale Price:

$106.81

Adding to cart… The item has been added

Adding to cart… The item has been added

3M™ Aerospace AC-130-2 Clear BMS5-162 Type I, Form 2S Spec Surface Pre-Treatment - 1500 mL Kit

PART #:

SGP5167

MFR PART #:

7010371666

Regular Price:

Our Price:

Our Price:

Sale Price:

$520.88

Adding to cart… The item has been added

Adding to cart… The item has been added

3M™ Aerospace AC-130-2 Clear BMS5-162 Type I, Form 2S Spec Surface Pre-Treatment - 50 mL Kit

PART #:

SGP5168

MFR PART #:

7000048184

Regular Price:

Our Price:

Our Price:

Sale Price:

$93.25

Adding to cart… The item has been added

Adding to cart… The item has been added

3M™ Aerospace AC-130-2 Clear BMS5-162 Type I, Form 2S Spec Surface Pre-Treatment - 500 mL Kit

PART #:

SGP5169

MFR PART #:

7100107766

Regular Price:

Our Price:

Our Price:

Sale Price:

$315.35

Adding to cart… The item has been added

Adding to cart… The item has been added

Approvals and Conformities

Boeing PN/Spec#

BMS5-162, Type I, Form 2S

Alternate PN#s

AC-130-2, AC130-2, 70-0052-0018-6, 70005200186, 051141-57819

Product Attributes

Country of Origin

Country of Origin

United States

Size

50 mL

Shipping Weight

0.2 pounds

ECCN

EAR99

Color Family

Clear

Manufacturer P/N

7000048184

Schedule B Code

3214.10.0010

Pack Quantity

1

Ship Dimensions

6 x 5 x 1 inches

Size

50 mL Kit

Spec

BMS5-162 Type I, Form 2S

Color

Clear

A sol-gel surface preparation for adhesive bonding of aluminum alloys, steel and titanium. Promotes enhanced adhesion as a result of the chemical interaction at the interfaces between the metal, the AC-130-2 and the primer. Helps improve process efficiency; enables many metallic substances to be prepared with a single method Up to 35% reduction in labor-time vs. PAA process; minimizes process flow time over Grit Blast Silane, PACS (tm) and PANTA (tm) Helps minimize Aircraft on Ground (AOG) time compared to traditional processes; ambient-temperature curing allows for field repairs Compatible with existing application techniques; brush, spray, wipe or dip application available Comparable mechanical results to surfaces prepared with the PAA process Reduction in process flow time yields a minimum of a 35% reduction in labor time.

INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING